The transmission system fully adopts imported linear guide rails, which have fast speed, high precision, low sound, and stable quality.

The electrostatic plate is made of original imported parts from Japan, and a large number of other spare parts are also imported products.

★ Two cutting heads, one for half blade cutting and one for full blade cutting. The half blade adopts a fixed lower blade depth to ensure the cutting efficiency of the half blade

The fastest cutting speed reaches 1000 mm/s.

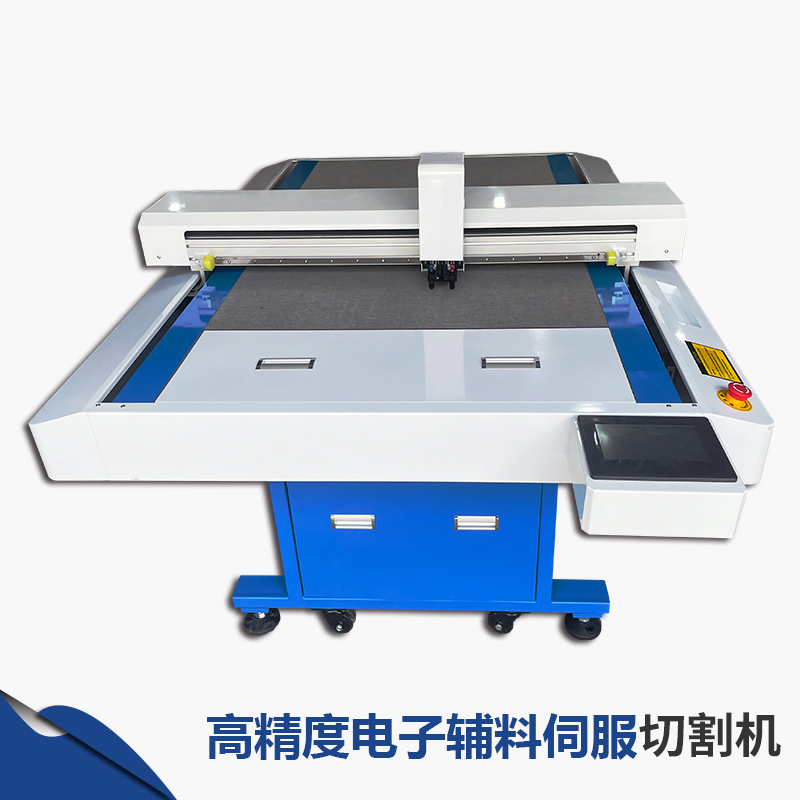

Electronic material cutting machine, adhesive cutting machine, provides professional solutions for sample making in the electronics industry. New force controlled machine heads and laser positioning have been added to achieve precise control of cutting pressure and positioning cutting, resulting in significant improvements in cutting efficiency and quality. Thanks to force control technology, the impact of table flatness on product cutting quality can be completely solved, and perfect half cutting and full cutting effects can be achieved by simply setting the pressure. It can locate and cut various printed circuits or electronic materials, and the DCG70 series uses vacuum adsorption materials. According to the different cutting materials and application industries, it can also be called electronic die-cutting machine, electronic material cutting machine, laser knife die plotter, adhesive cutting machine, film cutting machine, etc.

Main features:

Compared to the knife mold

1. Save mold opening costs; 2. Save sharpening costs, 3. Easy to modify

Compared to laser cutting machines

1. The edge of the cutting material is not black. 2. Cutting thin materials will not burn. 3. There is no glaring light during work. 4. Low cost of use

Three unique functions

1. Full and half cut cutting can be completed in one go. 2. Cutting accuracy up to 0.05 millimeters. 3. Can be drawn. 4. Equipped with an indentation strip, indentation and cutting can be completed in one go. 5. Positioning cutting function can accurately locate and cut various electronic materials. 6. Force controlled knife can cut perfect half cut effect

Four application scopes

1. Sample making of optoelectronic materials 2. Sample making of flexible circuit boards 3. Sample making of touch sensitive film switches

Main cutting materials:

3M double-sided tape, optoelectronic materials (light shielding, diffusion, reflection), insulation materials, thin film switches

Main application industries:

FPC, membrane switch, optoelectronics, cover film, etc

Jinde Ver16.51-OCA high-precision electronic auxiliary servo flat cutting machine parameter specification table

Specification and model JD-OCA-0906AJD-OCA-1209AJD-OCA-1509A

Maximum actual cutting area 900mm * 600mm * 1200mm * 900mm 1500mm * 900mm

Maximum material width 650mm, 950mm, 950mm

Loading content/method: Plane material OCA and other four layer electronic thin film materials; Satisfy batch cutting of 500mmx500mm

Transmission method LAN PORT, network port transmission

The origin coordinates can be set by oneself, and the cutting starting position can be set by oneself.

The standard cutting blade is 9U or 15U, and different blades are configured according to the thickness of the OCA material (9U for OCA below 1mm, 15U for OCA above 1mm).

The cutting material and thickness are suitable for various OCA or soft PVC four layer soft film electronic film materials, with OCA thickness ranging from 0.05mm-1mm. And various high-precision electronic soft material cutting

The cutting accuracy is suitable for cutting various circular or semi-circular shapes with R=1mm.

Chamfering accuracy can chamfer with R=0.5mm accuracy, supporting various shapes such as squares and rectangles

Half cut (cutting) accuracy: Cut the release film with a thickness of 0.05mm to 0.1mm, and do not cut the OCA with a thickness of 0.05mm.

Mechanical/software resolution

Aluminum plate platform precision mechanical resolution: 0.025mm/step; Software precision 0.05mm/step43mm thick high-precision pure aluminum profile honeycomb aluminum plate, aluminum plate platform precision reaches ± 0.1mm

Internal and external shape accuracy, shape accuracy: 500mmx500mm ± 0.1mm, spacing cutting accuracy (any two positions): accuracy within the effective range of 500mmx500mm ± 0.1mm,

Hole cutting accuracy: length 10mm x width 3mm ± 0.1mm,

CAD compatibility supports importing and exporting CAD formats, as well as formats such as HPGL

Crop software

Standard capability 1. Cutting software supports basic design drawing/editing/modification/array/saving drawings; 2. Edit cutting order and cutting path capability; 3. Support the function of editing starting and ending order

4. You can manually set the starting position for cutting. 5. There are more clipping, editing, and modification functions available.

Touch control panel with intelligent touch screen control, capable of performing functions such as movement, repeated cutting, and modifying blade depth testing after changing blades.

Cutting speed of ≥ 50 sheets per hour (12 sheets per hour, with a hollow length of 10mm x 3mm width)

Repeated cutting production touch screen operation, supporting one click repeated cutting production (start button).

Drive mode: high-precision pure digital servo motor and servo driver, 3-arc high-precision reducer, 8-axis high-precision control card for cutting machine

Power supply and voltage 110/250v 50-60Hz 120W (max); Air pump: 1.1KW; single-phase