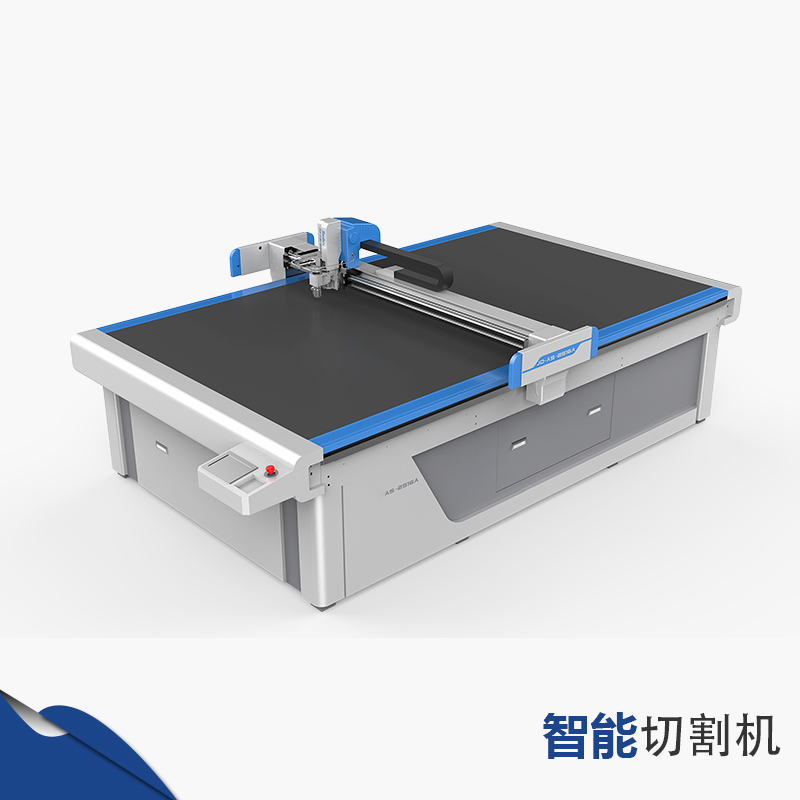

Functions and special feature

◇ Electric shock and head, strength, vibration frequency is high, up to 25000 times per minute.

◇ Cutting machine transmission system adopts imported gear, rack, cutting precision to achieve zero error.

◇ Using Servo-motor from Mitsubishi, With computerized control.

◇ The configuration of vibration knife, drag knife strokes, tools and optional half knife, cutter, slotted knife, knife, cutter, indentation knife and other tools, can achieve the office of line drawing, cutting, cutting, dotted half cut off all the cutting and milling cutter cutting, various materials, V-CUT slot milling, pressing wheel, indentation size the utility function and so on scratch hard materials.

◇ Fully automatic camera positioning function: automatic positioning and cutting of printed materials, without manual positioning can be cut out the outline.

◇ The type of rolling table design advanced, platform width can be customized size, no limit theory of cutting length, by vacuum suction design, super wind, strong suction (sample sheet is no longer difficult).

◇ The completely independent research and development of computer control system, namely the humanized operation interface, support for remote teaching, remote maintenance, remote upgrade, let the customer with more peace of mind.

◇ Any CAD software can be connected. It is widely used for plotting and cutting for the industries and sectors like garment, shoe making, cases, handbags, laser cutter molds plotting, lighting fixtures, advertising gifts, self-adhesive and color box packing.

◇ Optional charging rack and automatic feeding device

Jinde Computer CNC Cutting Machine JD-AS-A Series Technical Parameter Standard Table | ||||

Technical parameters/model | JD-AS-1410A | JD-AS-1813A | JD-AS-2516A | JD-AS-2520A |

Working characteristics | Computer operation and cutting machine are carried out at the same time to quickly complete the data transmission and can be used continuously. | |||

Cutting speed | Up to 1500mm/s | |||

Cutting thickness | 0.2-30mm | |||

Cutting materials | It can cut asbestos gaskets, rubber gaskets, honeycomb cardboard, plastic corrugated board, plastic hollow board, gray board paper, composite materials, rubber board, pearl cotton, EVA board and other materials under 30mm. | |||

Number of pens | 8 different sets of strokes: half knife, full knife, milling cutter cutting | |||

Positioning method | Infrared laser lamp | |||

The way to fix the paper | Vacuum adsorption and pneumatic mechanical fixation | |||

Cutting accuracy | ±0.2mm | |||

Repeat accuracy | ≦0.05mm | |||

Cut the circular diameter | ≧5mm diameter | |||

Transmission interface | Ethernet port | |||

Compatible software format | AI software, Autocad and Coreldraw can be output directly without conversion, and with automatic optimization. | |||

Instruction system | HP-GL and GP-GL | |||

CNC panel | Liquid crystal display | |||

Transmission materials | High-precision racks and gears | |||

Working voltage and power | AC 220V 380V ±10%, 50HZ; whole machine power 11kw; fuse specification 6A | |||

Type of motor | Fully imported Mitsubishi servo motor | |||

Vibrating knife head | The vibration knife head motor is 25,000 rpm, and the electric and pneumatic knife heads are available. | |||

Cutting area | 1400mm*1000mm | 1800mm*1300mm | 2500mm*1600mm | 2500mm*2010mm |

Appearance size | 2160*1680*1220mm | 2570*1990*1200mm | 3300*2250*1200mm | 3300*2660*1200mm |