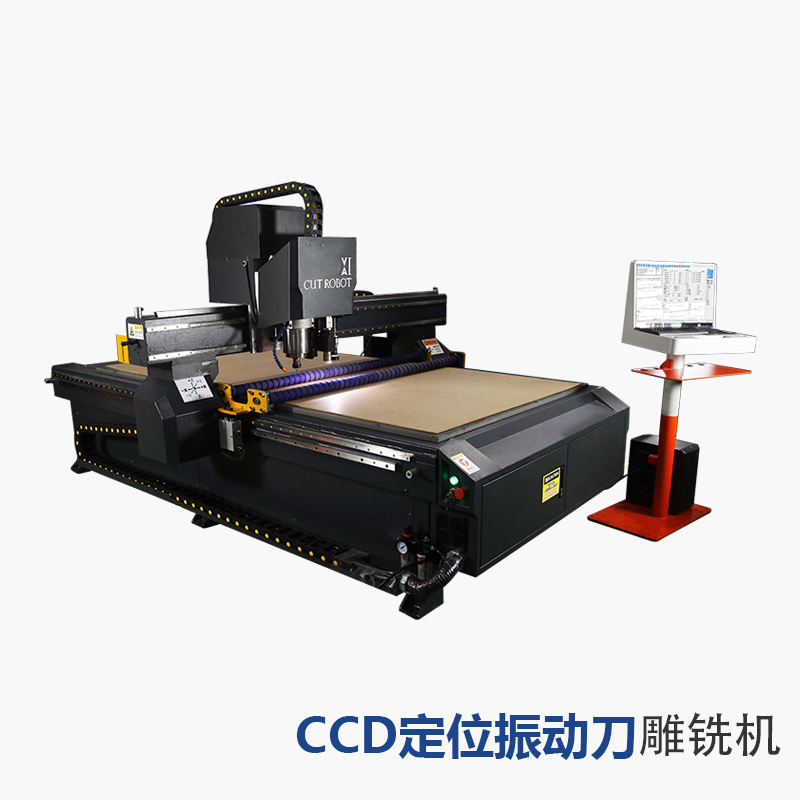

CCD intelligent vibration knife carving robot - expert in cutting soft/hard consumable materials,

When cutting materials with strong toughness and flexibility, we need a highly rigid machine,

A cutting machine that can cut both flexible and rigid materials,

For example, precise cutting of insulation materials for intermediate composite steel plates, asbestos gaskets, thin aluminum plates below 3MM, imported rubber pads, foamed PVC and other materials.

Functional Features

1. To fix and strengthen the fixed cutting table, it can be used as a vibration knife cutting machine, as well as a carving machine. It can be used for cutting various clothing multi-layer acrylic thick templates with milling cutters, cutting aluminum templates within 3mm, as well as insulating asbestos materials. It can also be used for advertising UV color printing acrylic KT and snowflake board CCD visual positioning followed by edge cutting

2. The system can be equipped with high-speed circular knives to cut special flexible materials, such as fiberglass, and can also replace vibrating sharp knives for harder materials, such as asbestos gaskets and rubber,

3. The CCD vibration knife carving and milling machine control system independently developed by Jinde, with intelligent network port control, can control high-speed camera positioning for carving, milling and cutting while completing the positioning and cutting of vibration or circular knives. In addition, advanced intelligent actions such as punching and cutting ports and punching circular holes can be optionally selected

4. The carving machine has a unique annealed square steel structure, reinforced with elongated crossbeams to ensure sufficient rigidity and ten years of no deformation. The machine comes with a rolling roller device that can roll and cut two layers of acrylic boards at once

5. The software has powerful operation functions and can read formats such as HPGL \ DFF \ PDF \ AI output from various industry software CAD. It also supports machine code cutting and has strong compatibility

6. The whole machine has a high degree of automation, is easy to learn, and meets the cutting needs of industries such as clothing, furniture, advertising, printing, and insulation materials. It only takes half a day of learning and training to get started

7. The intelligent high-definition CCD visual positioning camera combined with carving and milling, vibration knife cutting technology can accurately correct the position and angle deviation of the placed material in real time according to the actual size of the spray painted, and perform fully automatic angle rotation, scaling and vectorizing the cutting path before cutting

8. Independent control card, capable of connecting to intelligent network port LAN PORT and computer for operation

9. The cutting curve adopts vectorized spline curve optimization cutting mode, which can ensure high-speed cutting, smooth and round cutting, and accurate cutting of different curvatures.

10. Adopting high-strength and high-precision helical gear racks and linear guides, with good rigidity, high precision, and low noise, the high-voltage servo control motor and drive system ensure precise and high-speed cutting.

11. A high flow vacuum adsorption device with built-in powerful frequency converter control, delayed start-up will not affect the power supply. Standard equipment includes 8 automatic zone cutters, as well as sound-absorbing speakers and silencers, making it easy to operate and use even in quiet office buildings.

12. Other combination function modules can be optionally selected, such as inkjet printing module, equipped with combination vibration knife module, or more punch hole and customized punch shape modules. Please refer to our tool head configuration table for details.

CCD intelligent vibration knife engraving robot | |||

Technical parameters/model | JD-CCD-CNC1325S/H | JD-CCD-CNC1313S/H | JD-CCD-CNC0906S/H |

Spindle power | 5.5KW/3KW water-cooled spindle 24000rpm | 3.7KW/3KW water-cooled spindle 24000prm | 2.2KW water-cooled spindle 24000rpm |

Precision | ±0.02mm(±0.04mm) | ||

Maximum effective cutting speed | 18m/min(15m/min) | ||

The fastest empty running speed | 25m/min(18m/min) | ||

Transmission mode | XYZ shaft adopts linear guide rail, XY precision grinding oblique rack drive | ||

Motor & Driver | Huichuan pure servo/Leise hybrid servo | ||

Positioning method | CCD camera and laser light positioning | ||

Material fixation method | Vacuum partition adsorption | ||

Vacuum pump power | 9kw air pump | ||

Transmission interface | Ethernet port | ||

Instruction system | G Code, NC, HP-GL and GP-GL compatible formats, IPP-G1 compatible formats | ||

Engraving and milling tools | 3.175mm, 4mm, 6mm, 8mm, 10mm / 3.175mm, 4mm, 6mm | ||

Vibrating knife head | Vibrating cutter head motor 20,000 rpm | ||